Leak Testing Meets New Energy Storage Needs

Leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

Since the early 1990s Lithium ion batteries have entered industrial markets as energy storage technology for mobile consumer electronics and battery-operated tools. More recently, Li ion batteries have broken into new markets like battery energy storage systems (BESS) where they are used for load leveling, peak shaving and power demand management in grid-connected and autonomous power networks. Most promising seems to be their use in the market of electric vehicles ranging from electrical bicycles to high-performance passenger cars.

For applications in e-mobility, individual batteries are assembled in a module. Several of these modules are then combined in a so-called battery pack, which among others also comprises systems for cooling and battery management. All these components are integrated in a housing which protects the components inside. In the entire assembly, water ingress may lead to short circuits. In individual batteries, water ingress may lead to capacity loss and generation of hazardous substances due to chemical reactions with battery materials. So leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

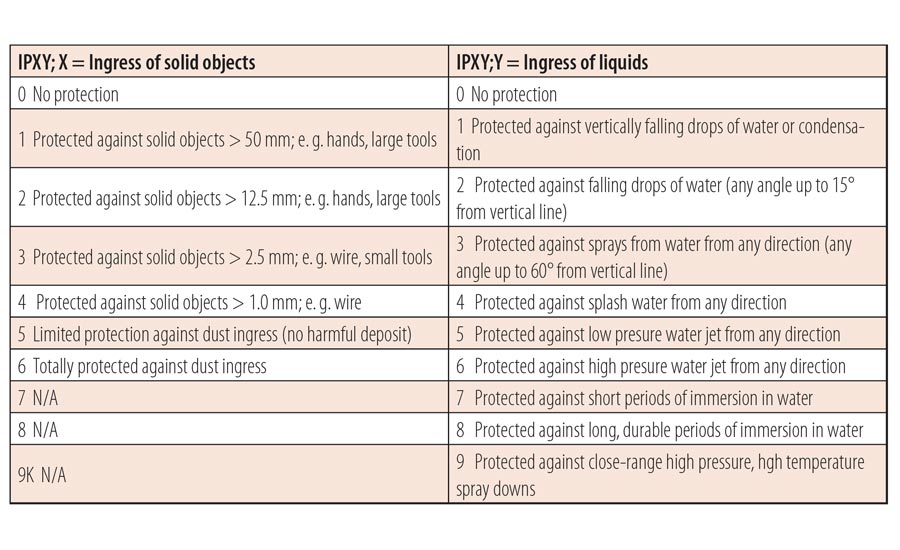

The requirements for leak tightness often are expressed in ingress protection classes. IPX7 defines protection against immersion of water. This simulates a breakdown scenario in a flooded underpass. IPX9K defines protection against a close-range high pressure water jet representing a cleaning scenario.

IP or Ingress Protection is a term widely used in electronics. It is expressed as a two digit number. The first number refers to its protection against solid objects and runs from 0-6. The second number refers to its resistance to water and runs 0-9. The higher the number, the greater the protection. (see table above)

Many electronics such as smart phones, cameras, headphones, watches, etc., are rated with these IP numbers. The ratings require manufacturers to test their product to ensure that they will pass the test and resist water at the specified depth.

Table 1: Protection against ingress of solid objects and liquids. Click here to see a larger version of Table 1.

Example of common applications:

- Automotive: engine and transmission control modules for major automotive companies and their Tier 1 suppliers

- Fuel/Delivery/Pump Stations: for the electrical enclosures

- Computers components and systems related enclosures

Many manufacturers have conducted their own testing for determining their individual tightness requirements against water ingress or IP protection. Once the rating is verified, one can test the product experimentally by lowering it into a water tank to the specified depth and verifying its functionality. This test is very messy and time consuming. It may be suitable in the R&D phase of a project but not in serial production. The transition from product development to industrial serial production also has to make the transition from a subjective and many times destructive test to a nondestructive, deterministic, and fast test with high gage R&R.

Test method and PASS/FAIL criteria

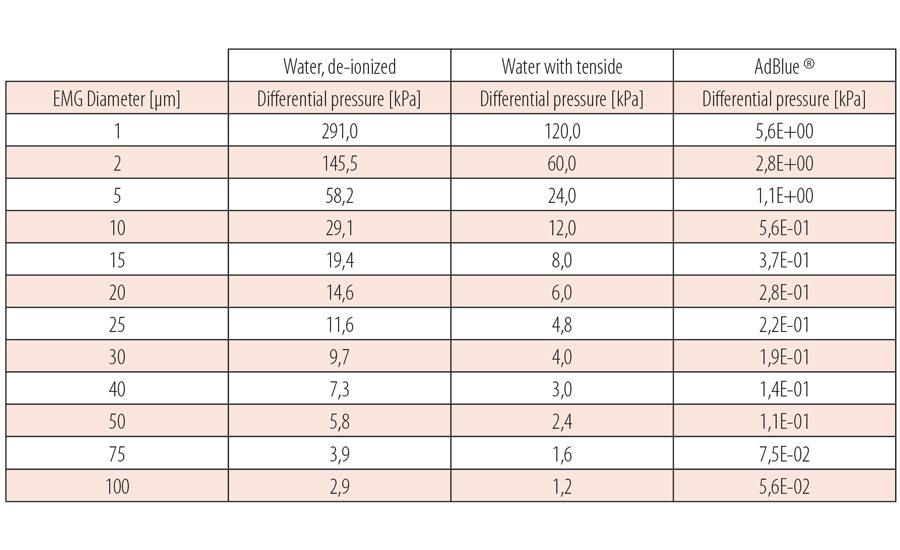

The phenomenological description of tightness against water ingress has to be translated into an industrial test recipe with selection of test method and PASS/FAIL criteria. From a theoretical point of view a good starting point would be to use the calculation as described in the following paragraph.

Table 2: Theoretical liquid ingress as a function of defect size and differential pressure (Click here to see a larger version of the table) Read More..